Design of the product plays a huge role in determining the possibility of mould making. Our expert designers and tool ma...

An Overview

We can determine if the metal part can be injection moulded based on its functionality. Compared to metal, equivalent plastic injected moulded parts have lower manufacturing cost and lower weight. These are the biggest motivators for manufacturers to make the switch to plastic injection moulded parts.

Advantages of Plastic over Metal

- Corrosion resistant

- Cost efficient

- Design flexibility

- May not need secondary operations

- Lower wastage

With Metal-Plastic conversion, we shall expect cost savings around 25-30%. This trend can be seen in the automobile industry where vehicle design building is largely focused on plastic components over metal.

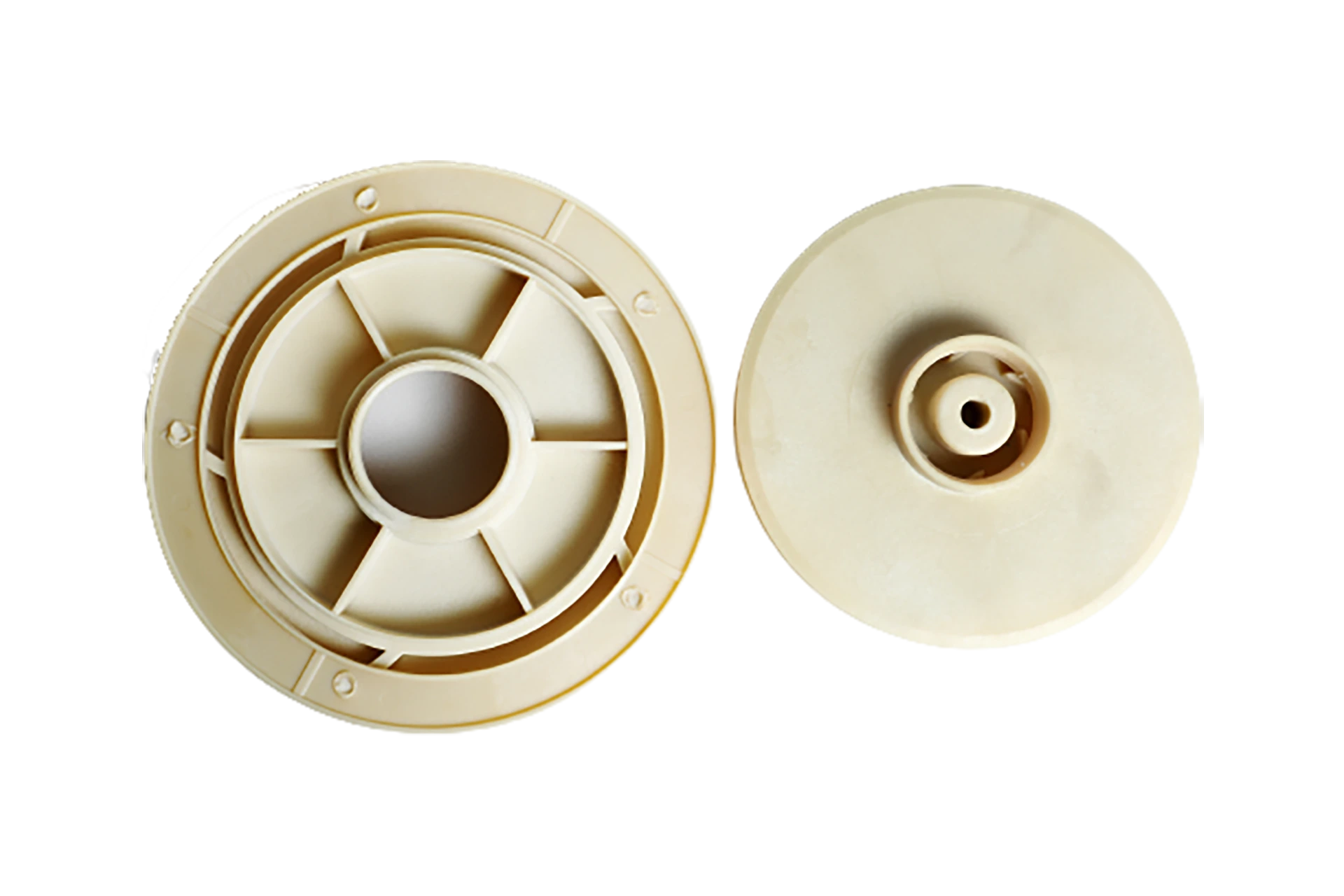

One other industry that Aqua Plastics can be associated with is the Pump and Motor Industry. Metal Impellers, Diffusers in the pumps are replaced with Plastic injected moulded components for the same reason. Aqua Plastics is a pioneer in manufacturing injection moulded Pump parts.

Check out our Pump and Motors section for more details.

Previous Story

Long Term Partnership

Related Posts

For ages, the motor starter boxes are made of metal which are heavy and bulky. If kept outdoors or in rain-prone areas...

Put correct shortname from your Disqus account in Customizer settings.